09134044667

شماره تماس :Get to know us better.

International group

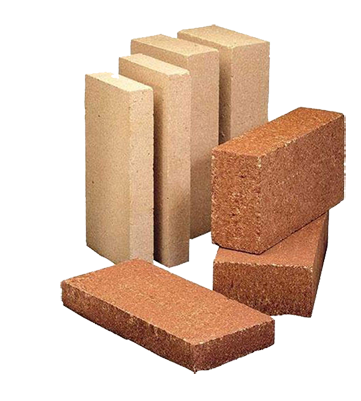

Yektaye Zayandeh Rood Facing Brick Factory, the largest factory producing industrial refractory bricks and building refractory bricks in Isfahan province, was established in 1995 (1374 in the Iranian calendar) by Mr. Ali Diyanti on a 40,000-square-meter land in the Habibabad Industrial Zone of Isfahan. In 2005 (1384), it successfully obtained the Standard and Industrial Research certification of Iran. The factory's equipment includes Hoffmann brick kilns, shuttle brick kilns, and tunnel brick kilns. The factory's brick production capacity is 150 tons per day of refractory facing bricks and industrial refractory bricks. The management and specialized staff of Yektaye Zayandeh Rood Brick Factory take pride in following a quality management system, prioritizing customer satisfaction, and are ready to accept orders from valued customers nationwide and from abroad for export to other countries.

Contact Us

Successful and completed

Product

Specialist staff